Disclaimer

This article translated from Koran Tempo that may contain copyrighted material, the use of which may not have been pre-authorized by the copyright owner. This material is made available for the purpose of giving information and knowledge. The material contained on the Astra Agro website distributed without profit. If you are interested in using copyrighted material from this material for any reason that goes beyond ‘fair use’, you must first obtain permission from the original source.

“No Palm Oil, No Life,” said Eddy Abdurrachman, President Director of the Palm Oil Plantation Fund Management Agency (BPDPKS) in early November in Bali. That sentence, according to Eddy, is very relevant to the fact that palm oil is the most versatile vegetable oil in the world.

Eddy said that palm oil is the most productive with the least land use for every ton it produces. “Imagine, palm oil products are needed to fulfill the needs of the world’s population, ranging from food ingredients, cosmetics, other body care and environmentally friendly energy,” Eddy said.

Erliza Hambali, Head of the Process Technology Division, Department of Agricultural Industrial Technology at IPB University, acknowledged that there are many uses for palm oil. In fact, because she thought palm oil could become anything, she researched and made products from palm oil.

“Initially, I made it into soap, which was easy. Then it continued, after soap I kept looking for what else had high added value,” she said. Since 2005, he has often sought the goodness of palm oil and socialized downstream products of the palm oil industry to ministries and other institutions.

Downstreaming the palm oil industry, Erliza continued, is the process of processing Crude Palm Oil (CPO) and Palm Kernel Oil (PKO) into higher value-added products. These products can be for export purposes or import product substitution.

“Downstream palm oil products are divided into three major groups, namely oleopanganese, oleochemicals, and biofuels,” he said. Oleopanganese, Erliza said, are food products derived from palm oil. “For example, cooking oil, margarine, shortening, and ghee.”

Palm oil, she added, can also be used as oleochemicals that produce soap, surfactants, detergents, biolubricants, shampoos, biomaterials, and bioplastics, among others. Palm oil can also be used as a biofuel which produces biodiesel, bioethanol, and biogas.

This was also recognized by the Director General of Agro Industry of the Ministry of Industry (Kemenperin), Putu Juli Ardika. Additional foreign exchange can be obtained from the export of downstream palm oil products. The indicators of achievement are the number of various types of downstream products and the ratio of the export volume of CPO / CPO raw materials compared to processed palm oil products.

“We noted that there are around 179 different types of downstream palm oil products and around 90 percent of the export volume is in the form of downstream products. Only about 10 percent of the export volume is in the form of CPO/CPKO raw materials,” he said.

Exports of palm oil industry products reached a total volume of 282 million MT with a total value of USD176.84 billion during the 2015-2022 period. From this export performance, the state through BPDPKS received export levy revenue of Rp 182 trillion.

The funds, Putu said, have been used around Rp 152 trillion to maintain the sustainability of national palm oil through the people’s oil palm replanting program, improving the quality of human resources, palm oil research and development, advocacy and positive palm oil campaigns, and improving facilities and infrastructure including mandatory biodiesel incentives.

Putu said, both oleopangan, oleochemical, and biofuel have a big impact on the country, both used to fulfill domestic needs and as export commodities. According to him, the performance of the cooking oil industry must be maintained because it is part of the provision of basic necessities for the community.

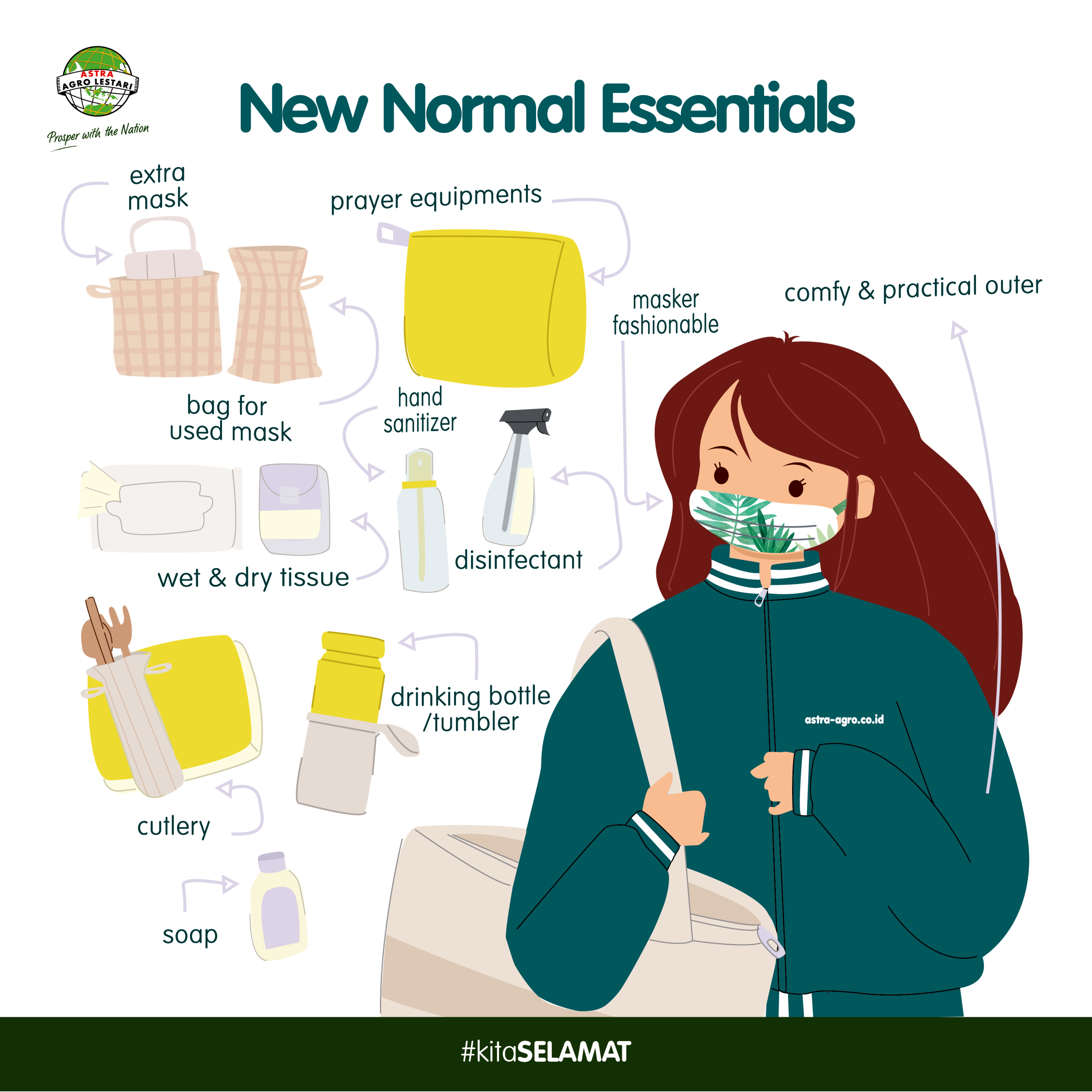

During the pandemic, the oleochemical industry that produces personal wash plays a very important role in supporting one of the M in the 3M covid program, namely washing hands. The biodiesel industry has grown significantly supported by the mandatory biodiesel policy which has increased from B20, B30, and currently B35.

The growing population, Putu said, is a large market for palm oil derivative products. “So oleochemical and oleofood products still have opportunities to be developed further. There are still many variants of modern oleo food products, which are needed as raw materials or as substitute materials in the food/bakery/horeca industry that can be developed with new innovations.”

Entrepreneurship in the downstream palm oil sector is directed by the Ministry of Industry to the manufacture of artisan products, including modern foods, food fat-based bakery-patisserie, soap, cosmetics, and oleochemical-based wellness products. Modern oleochemical products are widely used for personal care/personal wash that require certain physical properties/characteristics, which can be obtained from the development of palm-based biochemical innovations.

“Meanwhile, the position of the downstream palm oil industry is as a provider of raw / auxiliary materials for these entrepreneurs so that SME-level business activities can develop well,” he said.

The Ministry of Industry provides technical guidance to the industries of the three downstream products, including product standardization, technology development, and facilitation of commercialization of the results of domestic research and development. The Ministry of Industry also provides guidance on the business/investment climate of the industry, so that the number of business units can grow in processing the primary commodity of palm oil.

“What is also always maintained by the Ministry of Industry is the availability of industrial raw materials in the form of crude palm oil, so that factory operations continue to run smoothly.”

challenging downstream palm oil production routes to be researched, commercially developed, and marketed as modern palm oil-based new products. “For example, cosmetic/personal care products with local wisdom, which are favored by local residents and require palm oil derivative products as raw/auxiliary materials.”

Going forward, Putu said, the palm oil industry can compete if it fulfills these three things, namely, first, continuing to develop product engineering/production processes through dynamic innovation. Second, using CPO raw materials that are certified sustainable so that they can be accepted by the international market, and third, the scale of production of basic downstream industries (oleo food / basic chemicals) that are included in the global value chain in a borderless environment.

“The job of the Ministry of Industry is to support these three strategies through a series of pro-downstream policies, as mandated in Presidential Regulation No. 74 of 2022 concerning National Industrial Policy,” said Putu Juli Ardika.

Source: Koran Tempo